特点

好老库林CH-421S是除去铝合金毛刺的处理剂。它能代替常规型物理表面处理,也能除去只复杂微细(微米级)的毛刺,其它部分没有受到影响。

且,它能除去切削加工时产生的刀具痕,使材料表面粗糙度降低,以获得光亮。

人工处理,常规型物理处理不能实现的质量产品品质均一,提高产品品质,加快批量生产速度等......,CH-421S会实现。

HOROCLEAN CH-421S is a surface treatment agent special for aluminum alloy.

It removes without affecting smooth surface selectively tens of microns

burrs as well as several-micron-small burrs which have been formed in cutting

of aluminum alloys. This agent can work on interior of microscopic crossing

holes and intricate surface on metals evenly, which conventional physical

methods cannot achieve.

The agent is a single liquid type. It removes traces of bites,

improves surface roughness, and finishes the surface with metallic

luster. It is easy to handle and can processs a large number

of work pieces at a time and the uniformity makes quality better

and a delivery sooner.

|

|

使用方法

1 先除去沾在金属表面上的切削粉和油垢等。

2 用恒温装置CH-421S处理剂加温到60度。

3 材料浸渍在CH-421S里。不要靠在一起。

材料毛刺状态的不同,其浸渍时间也会不同。

本产品越使用处理时间越长。第一次使用本产品时,先做式样测试得出最佳使用条件。

处理100克的铝合金时,需要大约1公斤的CH-421S。

使用注意事项

长时间处理时,处理剂会产生大量的热,液温会上升,因此利用冷却装置保持规定的液温。

若一次进行大量处理时,也体会突然上升,十分危险。有可能处理剂会沸腾,使用者会烫伤,因此禁止一次性大量处理。

Before processing, cleanse off

scissels and oil an the surface of the work pieces.

Heat the liquid at 60℃ with a temperature-control device.

As repeatedly used, the liquid deteriorates and reaction time

gets longer. If you use the liquid after long interval,

a trial experiment for setting processing period is recommended.

The ratio of the treatment agent to the work pieces is about

100g aluminum alloy per 1kg treatment agent.

We recommend you test the agent beforehand if the liquid is

in compliance with your conditions.

For your caution, if the processing time becomes longer, the

liquid temperature becomes higher than standard level, which

may result in the damage on the work pieces. In such a case,

please adjust the temperature by a cooling down equipment which

keeps the liquid at a set temperature.

Never put a large amount of work pieces into a small amount

of treatment agent at a time.

It is quite dangerous as the liquid temperature may reach to

the boiling point and the worker may have burn.

The agent shows different effect on each pieces for its degree

of ragged burrs.

Please collect the data by testing the liquid with your sample

work pieces beforehand.

详细的使用方法按这里 详细的使用方法按这里

|

管理处理剂

本产品使用原液,绝对不许和水等混合。

处理剂越使用浓度越高。标准比重是1.75~1.78。做一下定期比重检查。

若浓度1.80以上时,加点水并调整规定的浓度。对浴量加点水1%的话比重就会0.01下降。

Liquid control

We

sell this liquid after composing the liquid in accordance with

the customer's intended use.

As this is the concentrate solution, please never dilite the

liquid with water or others.

Using the same liquid repeatedly leads to increasing the liquid

concentration. The standard index is 1.75 to 1.78. Please check

it regularly with the density indicator if the figure is within

the normal condition. In case the concentration index is over

1.80, please adjust it with a little water. 1% water to the

liquid amount decreases the gravity by 0.01.

|

其它

先CH-421S使用前测定并观察材料的详细的种类,大小,及毛刺的状态等。

利用简单的式样测试,要得出浸渍时间等使用条件。

了解使用条件后,按照月产量,日产量,开始准备引进处理设备。(负担实际费用,就可以借给式样测试机器,也可以派遣工程师。)

How

to use the liquid for removing burrs

Before

processing, confirm the material and mesure the size of the

work pieces, and burrs to remove.

With simple experiment devie, perform a practical experiment using CH-421S.

Decide some related conditions.

Estimate the number of work pieces to process to process per

month/day,then equip your factory with suitable scale of processing

device.

(We are ready to rent the trial experiment device and to send an engineer

at actual cost base.)

|

式样测试的准备物 Necessary

items for trial treatment

・ CH-421S (对应铝合金)

CH-421S treatment agent for aluminum alloy

・ 恒温装置 Temperature control equipment

处理剂加温任意的温度。

To keep the liquid

at a set temperature.

・ 苛性苏打 Sodium hydrate

用于废液中和。

To neutralize the waste liquid. concentration, to treat the waste liquid.

・ 温度计 Thermometer

能测定80度的温度计。

To be measurable

up to 80℃

・ 比重计 Floating gravimeter

能测定1.75~1.78的比重计。

To be measurable

around 1.75 or 1.78

・ PH测定试纸 pH measurement paper

废液中和时使用。

Necessary for waste

liquid treatment.

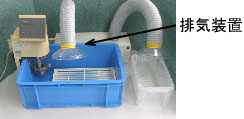

・ 废气处理装置 Exhaust gasss treatment

equipment

避免使用者吸入处理时产生的气体。

To avoid the worker's gas inhalation from the liquid.

・ 100mm×150mm×80mmH

容量 900cc

塑料容器 5个

Plastic containers

100mm x 150mm x 80mmH

5pcsof 900cc

|

|

|

实际的使用方法 Process

of removing operation

① 脱脂处理

Degrease

and cleaning |

先清洗材料表面上沾着的油垢。

脱脂处理后充分水洗。

To

remove oil on the work pieces, follow the conventional

methods. Wash the work piees thoroughly with water for

prevention of mixing abstergent into treatment agent |

② CH-421S処理

CH-421S treatment |

液温60度。浸渍处理。

处理时产生气体。

Immerse work

pieces in 60℃ liquid.

Treatment liquid produces gases.

▲加温装置 |

③ 回收槽

Collecting

bath |

回收槽里准备着清水。处理后用水水洗。

Rinse

treatment agent out of work piece surface in a water bath. |

④ 水洗

water cleaning |

流水水洗。

Clean the work oueces

in sufficient amount of running water |

⑤ 纯水洗涤

Cleaning

with pure water |

防止材料的干燥并水垢。50度的纯水清洗。

Rinse

the work oieces in 50℃ pure water. Effective to avoid

the water strain on the work pieces and dry with a clean

air. |

⑥ 干燥

Dry |

利用空气鼓风使干燥。

Blow and

dry with a clean air. |

⑦ 完成

Finish |

品质验证/包装。

Quality checking, packaging |

|

廃液処分方法

失效的液体先用水稀释,再用中和剂稀释,最后委托专门的回收人员处理。或者按照以下的处理处置。

How to dispose the waste lliquid

About waste liquid, ask professional

disposal contractor to deal with it. Otherwise dispose it by

following the instructions below.

|

废液处理工序 Process

of disposing waste liquid

① 稀释废液

Diluting

waste liquid |

回收槽的水和废液一起混合,再加上适当的量的水,稀释20倍以上,使降低浓度。

Mix

the waste liquid with water in the collecting bath until

it reaches a concentration of less than 5%. |

② 中和处理

Neutralization

treatment |

若对废液100公斤慢慢加上24%苛性苏打25公斤中和。

PH测定试纸的标准比色卡黄色比较,调整中和至PH7。

Add

25kg of 24% sodium hydroxide solution per 100kg of waste

liquid little by little.

Adjust the neutralization till pH-test paper indicates

yellow 7

.

▲PH测定试纸 pH mesurement paper |

③ 凝聚处理

Coagulation treatment |

对中和后的液体100公斤加上3斤G-flake(小片中性处理剂)。用G-flake可以进行不纯净物质和水分离。

Add 1.5kg of G-flake per 100kg of

neutralized waste liquid, and stir the mixture slowly.

Turbid flocks of impurities coagulate off the water the

liquid.

▲ G-flake |

放置一天。

Leave

the work pieces for one day. |

④ 脱水并过滤

Dehydration and filtration |

排出上澄液,把剩余的污泥用滤布等脱一下水。

Drain

only the clear supernatant liquid after precipitating

impurities out of the liquid and hydrate the bottom sludge

with a filter fabric.

▲SUS筐 |

▲滤布 |

|

⑤ 排水

Drainage |

上澄水和脱水的水经过活性污泥处理,生活排水排出。

Drain

the clear supernatant liquid and digestive liquor little

by little mixing active sluge treatment in a sewage treatment

equipment facility. |

⑥ 废弃不纯净物质

Disposal

of the impurities |

处理后的污泥使干燥,检查废弃物质溶出试验进行评估,没有环境荷载的话最后掩埋处理。

Dry the dehydrated and precipitated

sludge under the sun. And landfill them after making sure

that it has no adverse impact on environment by the dissolution

test. |

⑦ 处理完成

Finish |

水质试验/掩埋处理(委托产业废弃物处理行业人员)

Quality

check of water, landfill the waste (ask the job to an

industrial waste disposal contractor) |

有关废弃物质,请确认各个地区的行政环境课。为了保护环境,一定要遵守各个地区的环境标准,进行适当的处理。若建立不了处理方法及没有确认安全的情况下,绝对不许使用本处理剂,请返还制造厂商。

Please inquire your local government as

to the waste liquid disposal and abide by the rule to protect

the local environment.

When you have a difficulty in finding the way to dispose it

or you cannot handle it safely, please send it back to the manufacture.

Please never continue to use the waste liquid.

|

制造厂商

福井县鲭江市丸山町2-4-7

TEL 81- 0778-51-7155 / FAX 81-0778-51-7440

制造工业药品『登录号码井16号』

销售工业药品『登录号码263号』

株式会社 北 陸 濾 化

Manufacturer

2-4-7, Maruyama-cho,Sabae, Japan

Tel 81-0778-51-7155 / Fax 81-0778-51-7440

Certification of industrial chemical production (registered

No.16)

Certification of inustrial chemical sales (registered No.263)

HOKURIKU ROKA CO., LTD |